Our second “Plastic Material” page is of Nylon Picks:

A hugely popular and ever-present material for the manufacture of instrument picks is Nylon.

Nylon Picks use a very versatile material formed into fabrics (along with Rayon) invented at Dupont by Wallace Caruthers. Its silky petroleum thermoplastic nature lends to it being used in fabrics, and, lucky for us, in picks.

It is the second material to come on stage after Celluloid as a plastic replacement for animal parts. You might respond to it being second to ask about Bakelite, but that really didn’t get used for picks. It’s brittle and unforgiving.

The qualities of nylon picks…

While a durable material in general, Nylon is bendier and it will sheer apart a little more easily than some harder or stiffer materials if very thin. It can also wear down sooner than some other materials for picks. But still, it is a pretty durable material overall, all thin picks can break, with the exception of carbon fiber.

Nylon picks and the Fernwood Flasher?

In inclusion to its slightly less durable nature, the manner in which these picks are manufactured often leaves some “flashing” left over on an unfinished edge. But still, it wears fairly well. It is durable enough that a pro can use it for several gigs if it isn’t too thin. It won’t sheer as quickly as celluloid when thin, but the flashing left during manufacturing may have to be removed by sanding or using a knife.

Why Dunlop (who introduced its use in picks) and others use nylon:

Nylon is a very ubiquitous and affordably-made product. Someone can easily budget for replacing the picks as needed. Ten or so can be bought for as little as 5 bucks. That is USA dollars of course.

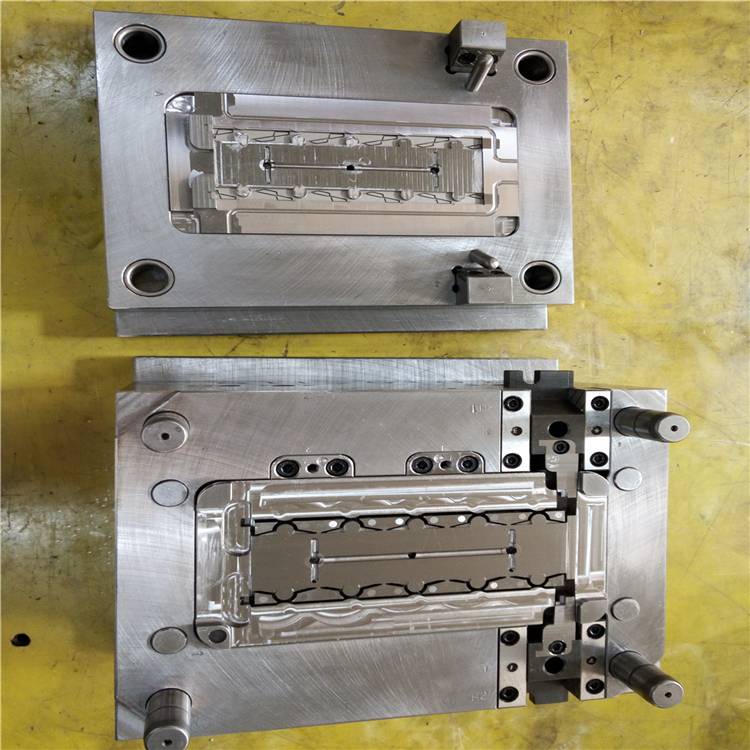

The process of making and also of forming nylon picks is desirable to manufacturers because of the repeatability and low relative cost. And it isn’t the same fire hazard that Celluloid is.

Another advantage in the manufacturing of nylon picks:

One really great quality of the nylon picks is how well they can be embossed with their grid-like textures to aid them with how grippy they are. Branding, names, and patterns are molded into the thermoplastic and even thicker models hold in the hands a bit better than our previously covered material, Celluloid.

The playing edge may come out with a little bit of material as mentioned, and that means you might want to sand them if you prefer to have no sloppy tips. The molded textures can be pretty wonderful and it’s not something easily done with other materials. Nylon picks with textures on them exhibit a high resolution to their shaping.

But a downside to the grid-like textures is the less workable add-on of pick grip materials such as cork and most nylon picks ARE textured at their grip.

The manufacturers of nylon picks:

A major manufacturer of nylon picks called Dunlop (Jim) and the wildly popular and the once rarer Herco “Holy Grail” picks are now available through that company. It is a great pick, also their nylon jazz picks are popular. However, the most flexible .63mm and other picks shine as some of the most renowned flex picks for strumming.

There are Dava picks with handles and Fender picks made of nylon, and Attak picks are nylon. There are likely a dozen makers using various forms of nylon picks.

What about the tone and feel of nylon picks?

There will be at least some depth to the tone and a bit of “flappiness”. For strumming, they are generally great picks, one of their better qualities. They will grip better than celluloid picks particularly if thin. And while it is hard to describe, the tone is definitely different from celluloid, which has a more medium sound.

Fragile or strong? It depends…

Nylon will wear and as we all know, nylons (stockings) will tear fairly easily as a sheer fabric. The strand-like quality of this product which involves high-pressure processes with ammonia is very popular. The Romance with Nylon is very historic and long-lived. Stockings get runs in them, and a nylon pick might sheer if thin enough, but if you actually consider the material itself, it is a fairly strong substance and flexible and decent sounding. Acrylic so thin would be more brittle and prone to breakage.

Imagine using a wooden pick of a similar thinness as a strummer’s nylon pick, even with the right wood, it would break much more easily!

More on its manufacture…

A condensation polymer, there are different versions and a wide variety of makers. Rayon is a related product but I don’t know of a so-called Rayon Pick.

Above about 1 mm, and well into 2mm, nylon is reasonably stiff with just a slight amount of flex, a thumpy tone with a little less bite. A smooth finish ring makes it useful even in Jazz and Folk. a 1.4mm nylon pick will be stiff, but there is still a vestige of flex there. And it’s a softer, less brittle material.

With a Durometer class D hardness of 80 and a Sheer Strength of 10,000 PSI and a steel coefficient of friction of .25, it will make a scrape-like tone as it slides against the strings.

An example of a nylon pick (I review a few on this site).

A Herco Flex 75, at almost 1.0 mm still gives a touch of flex and a clip/slap to the tone, it will work in rock and folk, on acoustic and electric, mandolin or banjo, but perhaps not for bass as much.

Compared to, say, an acetal pick, it has quite a bit more flex at 1mm but is not huge, it is enough to make it “slap” on the strings.

Try a .7 to 1.5 mm and see if the flexibility and tone work for you in some of your playings. There are even sub-.40mm picks of the stuff. A .5 or thinner will really flex a lot!